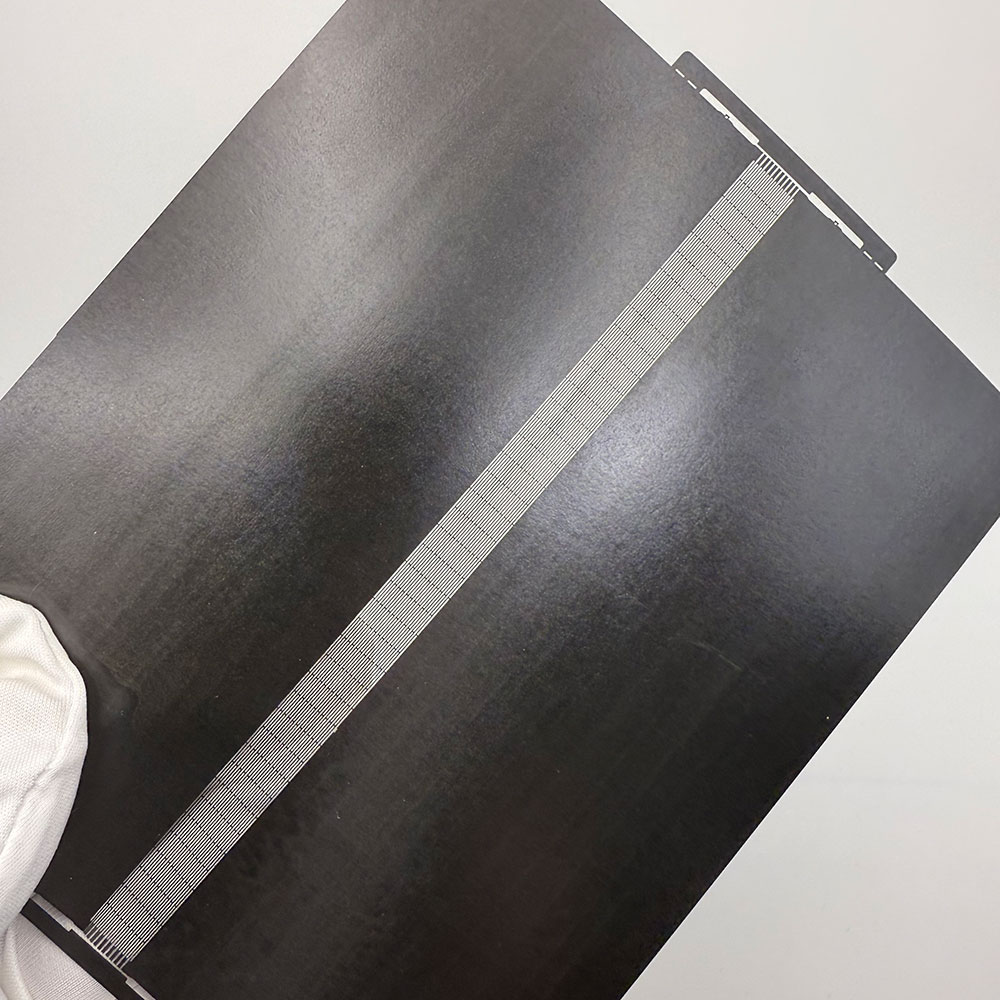

Laser cutting film for foldable phones

Laser cutting film for foldable phones

Materials: GLASS

Process:

Laser Cutting

Processing thickness: 1-50 mm

Cutting shapes: circular, elliptical, oblique circular, stepped window, oblique, and any other shape.

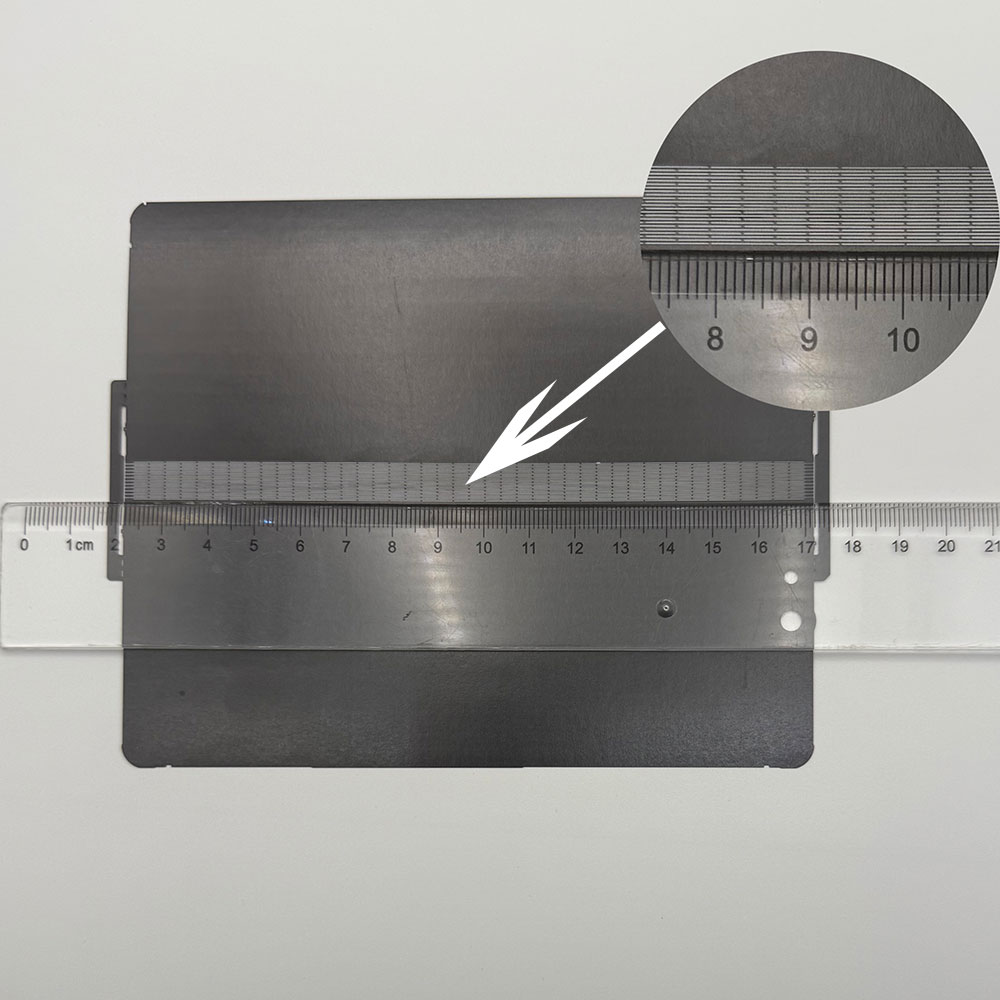

Minimum aperture: 0.02mm

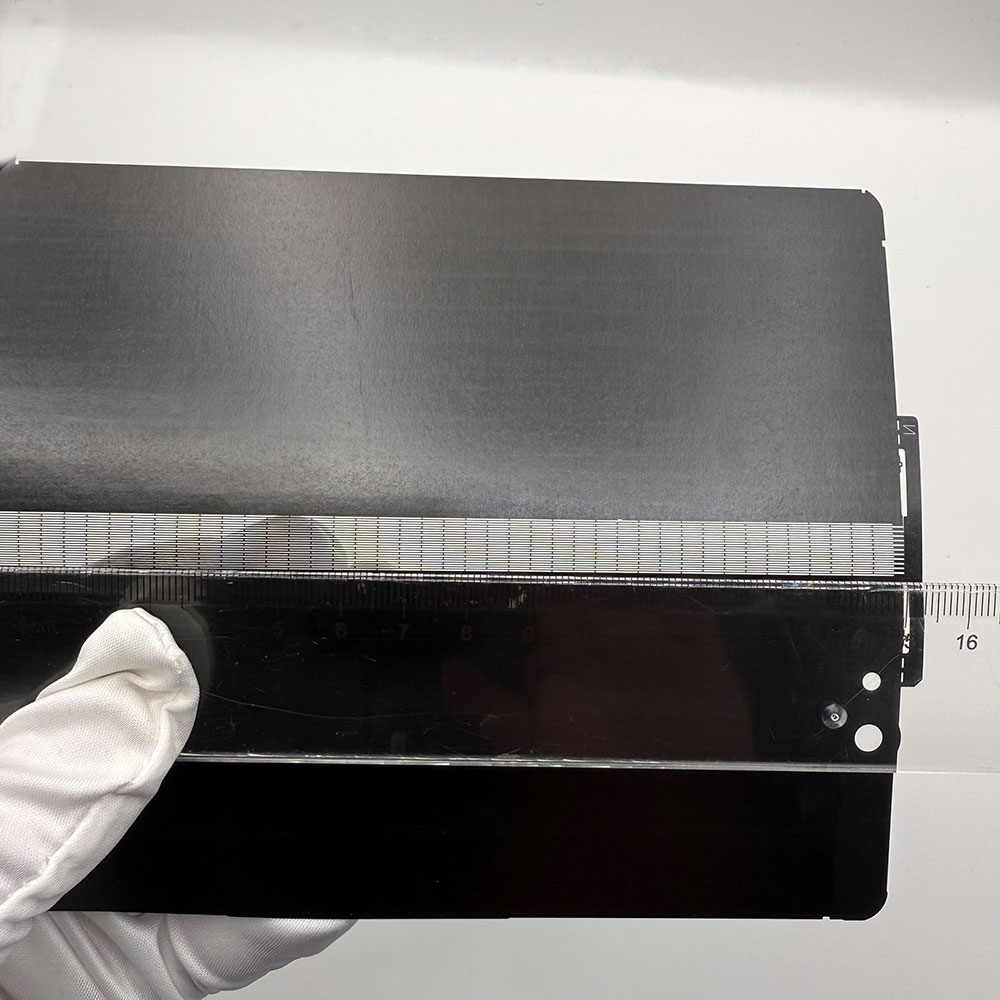

Accuracy:smooth without any broken edges.

Functional Features:

Laser cutting ensures good surface quality, smooth and no broken edges

Application industry:

Medical industry electronic equipment household appliances

laser cutting uses a high-power density laser beam to irradiate the material being cut, which quickly heats the material to the vaporization temperature and evaporates to form holes. As the beam moves on the material, the holes continuously form narrow (such as about 0.1mm) cuts, completing the cutting of the material. Laser cutting is the use of a focused high-power density laser beam to irradiate a workpiece, causing the irradiated material to quickly melt, vaporize, burn, or reach the ignition point. At the same time, high-speed airflow coaxial with the beam is used to blow away the molten material, thereby achieving the cutting of the workpiece. Laser cutting is one of the thermal cutting methods.