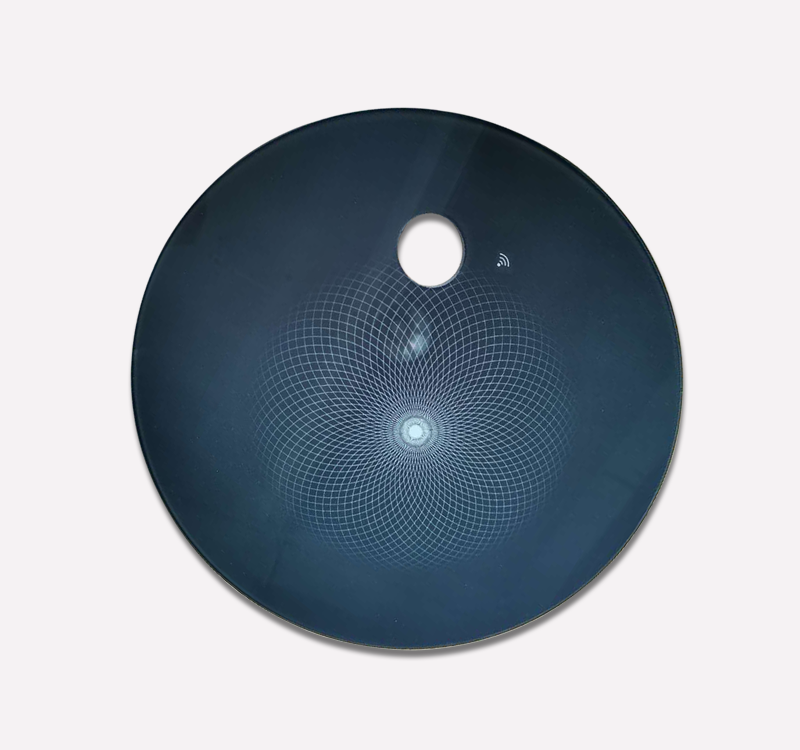

glass panel for floor sweeper

Name: Floor Sweeper Panel Glass

◆ Material: Tempered glass, ultra white glass, ordinary green glass

◆ Thickness: 6MM ± 0.05

Size: 350 * 380 * 6MM

◆ Process: Cutting - Fine Carving - Edge Polishing - Cleaning - Tempering - Screen Printing - Inspection - Packaging

Quality: 100% return processing for unqualified quality

◆ Sample making: Samples/pictures can be provided for sampling

◆ Price: Depending on style and quantity

◆ Hardness: 8H

Explosion proof grade: IK10

Heat resistance: 250 ℃ -450 ℃

Production cycle: 7 days

◆ Process effect: The product is safe, beautiful, and high-end

◆ Suitable for: intelligent sweeping machines, various electrical panels

The glass of the sweeping machine is cut into glass of the same size according to the customer's drawing from the original glass sheet. Glass cutting is mainly carried out by an laser glass cutting machine. The automatic cutting machine has the characteristics of precise size, no broken edges, and no distortion; The cut glass is then subjected to CNC edging treatment, which can prevent the glass from being cut by hand. Common types of CNC edging include glossy and matte edges; Glass is subjected to high-temperature treatment in a physical tempering furnace after CNC edging, which increases its hardness and makes it less prone to breakage.

Tempering is divided into physical tempering and chemical tempering. Physical tempering is used to temper large-sized glass and to process glass products with high tempering strength requirements. After the tempering process is completed, the glass surface also needs to be screen printed with patterns, which requires a combination of screen printing screen and screen printing ink. And print according to the customer's pattern and logo.

The silk screen adopts an imported 300 mesh diagonal screen for silk screening, so that the printed pattern has no serrations or tooth edges.